MWD / LWD

Measurement While Drilling / Logging While Drilling

Mesa West Directional can meet any down hole need with our extensive collection of motors and jars, as well as state of the art MWD / LWD tools. With all equipment in-house we are able to keep you drilling.

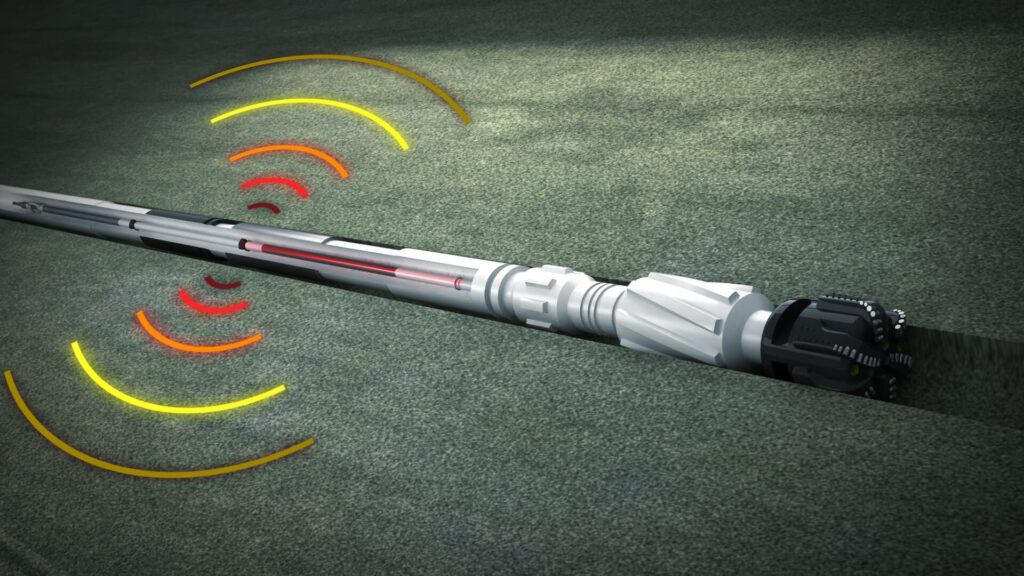

DTT – DUAL TELEMETRY TOOL

Advanced directional drilling technology that provides downhole tool reliability by transmitting EM and Pulse signals simultaneously. Mesa West’s Dual Telemetry Tool is a high data-rate, mixed telemetry MWD system that delivers leading-edge performance and technical innovation at a cost-effective price point.

When aggressive drilling is needed, we have optimized this tool for operation in harsh drilling environments, such as the Permian Basin. Mesa West’s DTT is purposely designed for operation in challenging non-homogeneous formation lithologies. The MTS is calibrated to maximize drilling efficiency in all mixtures of brine and oil-based muds as well as in under-balanced mist/foam applications without reconfiguration of the downhole tool string or BHA.

- Generic variables

- Generic controls

- Raw data surveys

- Tool retrievability

- Faster surveys – Pumps down EM surveys are made during connections minimizing Non-Productive Time (NPT).

- Higher Aggregate Data Rate – Combining EM and MP communication channels allows high resolution data density

- Superior Reliability – Downhole redundancy reduces trips for tool or formation issues.

- Increased Data Log Density – High speed asynchronous data telemetry (MP and EM independently broadcast) to maximize drilling data acquisition

- Increased ROP – While sliding, the EM channel achieves higher TF updates to make building curves and drilling tangents faster

Positive Pulse System

Our mud pulse system is a fully featured MWD system with three axial accelerometers and magnetometers with gamma. All of this data is gathered during the drilling operation and transmitted to the surface via pulsations in the drilling fluid. Our wireless surface computers collect and decode the pressure pulses and interpret the data for the client and directional drilling engineers. All of the data can be logged and/or streamed to the client’s data management system.

• Industry standard “Accurate, Reliable, Durable”

• Long battery life [400+hrs]

• Retrievable design can be re-inserted without tripping

• Operates in a variety of collar diameters, from 3.5” to 9.5”

• Flow rates from 50 to 1200gpm

• Short radius build rates to 80 degrees per 100 feet

• Not limited by depth or formation

• High temperature capabilities to 175° C

• Simple transport and on-site assembly

• Low maintenance

• Adaptable tool configuration and programming flexibility

More On Positive Pulse

The positive pulse measurement while drilling system (PP-MWD) principle is based on the temporary restriction of drill-string mud flow to create a series of pressure spikes that form a communicative pulse waveform that is decoded using surface equipment. Downhole configurations are fully modular adding the flexibility of adjustments specific to BHA. Reliable surface decoding is further enhanced with the added option of wireless systems for long-range communication between rig and command center. Quality sensor measurement is made possible through industry standard magnetometer and accelerometer packages, including API standardized gamma ray modules. Downhole tool is fully retrievable and re-insertable for added confidence in lost in hole situations.

- Directional, vertical, horizontal and re-entry wells

- Short radius slimhole applications (3.50in tools)

- Logging While Drilling (LWD), gamma, annular pressure, vibration

- High operating temperature (175°C) and pressure (20,000psi)

- Wire-line retrievable and reinsertable design (minimum 2.25in I.D.)

- Available real-time gamma measurements for LWD (focused gamma available) downlink capability for selectable operating modes with proven software and firmware for efficient decoding.

- Adaptable tool configurations and programming flexibility

- Long battery life with Rotary Flow Switch (RFS) option – Reliable and proven design with mud telemetry not affected by formation or drilling fluid resistivity

EM Electromagnetic

Electromagnetic (EM) systems are very similar to mud pulse systems in that they operate with the same basic sensors and power supplies the only difference is communication of data. The EM tool transmits a magnetic pulse or electrical current through the ground to an antenna (ground stake).

• Low-cost, reliable replacement to mud pulse systems

• Underbalanced drilling

• High-speed drilling where fast data rates are required

• Low-pressure formations or lost circulation situations

• Proven design with high reliability, MTBF over 2500 hours

• Data transmission from depths up to 20,000+ feet with a downhole antenna

• Real – time Annular Pressure, Drill Collar Internal

Gyro Services

Mesa West stays ahead of the curve with the latest in gyro surveying technology. We can enhance your visibility with a full complement of true north-seeking gyros, MEMs, ‘state-of-the-art’ mini-inclination sensors or durable single shot or dual shot technology.

Leave it up to us to determine which technology is best for your project.

- Gyro Directional Surveying

- Drop Gyro

- Motor and Whipstock Orientations

- Surveying in reduced I.D. drilling or producing well applications

- GeoTechnical

- GeoThermal

- Water Wells

- Mining

- Constant, real-time reporting for immediate monitoring

- North-seeking capability in standard and hot hole versions

- Drift I.D. down to 1.300”

NEAR BIT TECHNOLOGY

Mesa West utilizes near bit subs that are designed to be used with our MWD/LWD fleet. The Near Bit Sub enables measurement of inclination and gamma count data approximately two feet behind the bit. Data is wirelessly transmitted around the down hole motor to the MWD System. The resistivity log measurement aids in calculating water/oil contact and helps evaluate permeability and porosity.

- Inclination and Azimuthal gamma at the bit

- Real-time bit information

- Ability to remain in tight geological formations [easier to stay in the zone, easier to get back in to the zone]

- Enables quicker response time when issues arise

- Available in 3 sizes: 4 3/4″, 6.5″, 8″

- Provides accurate inclination and rotation speeds, at the bit, up to 250RPM

- Azimuthal gamma ray provides clear “up” and “down” readings

- Seamless, wireless link to MWD system

Resistivity

Access The Most Productive Zones Of Your Well With Resistivity Logging Services

Record below the sub-surface to identify where hydrocarbons are located in your reservoir. Resistivity logging-while-drilling (LWD) tools gather data determining the balance of formations filled with water versus hydrocarbons. The resistivity log measurement aids in estimating water or oil saturation to evaluate producibility of the formation.

Mesa West offers a versatile resistivity tool with multiple options for depth of investigation (DOI) and multiple frequencies of phase and attenuated values. This allows confident geo-steering through complex geological structures, while maximizing exposure of the well-bore to the most productive zones.

- Precise wellbore placement and petrophysical analysis

- Detect water zones and avoid contact

- Stop precisely at desired casing or coring points

- Navigate reservoirs with dip angle and lateral thickness variations

- Maintain desired distances from bed boundaries

Make An Appointment

Please contact us below with questions, quotations, or appointments. Someone from our team will get back to you promptly.